A wide hem presser foot is a universal presser foot that makes double turned and topstitched hems, without you needing to mark, pin, or press. It turns the fabric under twice and stitches it down, eliminating two pressing steps. The guide on the foot turns the raw edge under and allows it to be easily stitched into place, giving you professional looking turned hems.

Everything you need to know about the Madam Sew Wide Hem Foot Set

With the wide hem foot set, you can sew hems of 1/2 inch, 3/4 inch and 1 inch wide. There is a foot for each width. The final width of your hem may vary slightly depending on the thickness and weight of your fabric, as well as your sewing technique.

Some people might be more familiar with the rolled hem foot or the flat hem foot-- the smaller brothers of these feet. They come with the 32pcs ultimate presser foot set, # 30 and #31. These feet both create a similar delicate and very thin hem for lightweight fabrics, perfect for finishing blouses or summer skirts. The difference between these feet is that the final hem produced by #30 (rolled hem foot) is slightly rounder, as it escapes the back of the foot through a curved groove. #31 (flat hem foot) creates a flattened hem.

PARTS OF THE ROLLED HEM FOOT

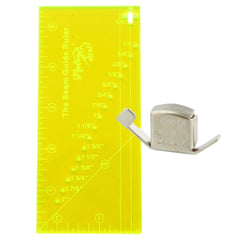

The wide hem foot is a universal presser foot on which a guide with a small curled fabric folder is attached to prefold the fabric before it reaches the actual presser foot.

There is a thumb screw to adjust this fabric guide. You can move the guide left to right to position the hem edge under the needle. You can reposition your needle as well to get the hems right.

DIMENSIONS

- Presser foot measurements: 2” x 1 ¾”

- Fabric folder size: 6/8”

- Thumb screw moves the guide 3/16” left to right

USES

With these feet, you can make 1 inch, ¾ inch, and ½ inch double folded hems on a variety of projects like:

Apparel: skirts, pants, shorts, blouses, shirts, etc.

Home decor: curtains, tea towels, napkins, sheets, tablecloths, etc.

On long, straight hems a wide hem foot works really well and saves a great deal of time, but it can also be used for the curved hems of a skirt or a round tablecloth. Curved folds are always a bit tricky, so just like you would do without this foot, We advise you to baste stitch the circle first, and trim a little to make the circular fold neat and tidy.

You don’t necessarily need a corner to start, the wide hem foot can be used perfectly for tubular hems.

Example of a curved hem on a skirt.

Medium weight fabrics work the easiest, but you can use a wide hem foot with a wide variety of fabrics like lightweight curtains or tablecloths.

ex. Lightweight curtain

ex. Tablecloth

COMPATIBLE SEWING MACHINES

All snap-on sewing machines except Bernina and PFAFF machines and some Husqvarna Viking models.

You can use this foot on:

• a Bernina if you have the Bernina adapter + a low shank snap on adapter

• a Pfaff or a Husqvarna Viking or on all screw-on machines if you have the low shank adapter

• a high shank machine if you have the high shank adapter

HOW TO INSTALL THE WIDE HEM FOOT ONTO YOUR MACHINE

The Wide Hem Foot is a universal snap-on presser foot for low shank sewing machines. You just snap it on and off your presser foot holder.

With the right adapter, you can use the Wide Hem Foot on almost any sewing machine:

The Low-Shank Snap On Adapter for a Pfaff, Husqvarna Viking (certain models) or any low-shank screw-on machine.

The Bernina Adapter + the Low Shank Snap On Adapter for a Bernina Machine

The High-Shank Adapter for a high shank machine.

For more information, visit our detailed blog post about shanks and universal presser feet.

Screw on machine, Pfaff, or Husqvarna Viking

Bernina

USER INSTRUCTIONS

Sewing with a wide hem foot is not difficult, but putting your fabric in the folder can be a bit challenging, as well as ending when you’re sewing a tubular hem, and sewing over seams. Reviewing these tips can help

TO START

There are several methods to get the fabric in the folder at the start, and it might need some practice. Always test on a scrap.

For a flat hem starting at a corner, slide the fabric into the fabric folder and pull the fabric under the needle keeping it double folded. Some people press the first few inches into a double folded hem and then slide the edge of the fabric into the guide of the foot. This is not possible with tubular hems.

For tubular hems, or when starting hems somewhere other than the corner, you can start by pressing the first 3 inches with your iron. Make sure to press up the hem width twice. Then, put the pressed hem under the foot-- without using the fabric folder-- just put the fabric underneath the curl. Put the presser foot down and sew a couple of stitches and backstitch. Put your needle down, lift the presser foot, and wriggle the fabric in and around the fabric folder, keeping the sewn part under the presser foot.

You can of course use this technique for flat hems as well.

SEW AWAY

It is useful to have a stiletto, a pin, or an awl at hand to help you pull the fabric through the fabric folder of the guide and up to and under the presser foot.

Never start on a seam.

Lower the presser foot and decide if you need to adjust the guide slightly left or right (loosen the thumb screw) or if you need to change your needle position right or left.

For a normal hem, use a straight stitch appropriate for the weight of your fabric. Once you start sewing, the foot will do the turning under.

If you want to work with decorative stitches, you should start with a simple decorative stitch, something open and uncomplicated. You can use wing or hem stitch needles to have an original effect.

Begin sewing and allow the fabric to feed freely into the fabric folder. As you are sewing hold the fabric so it roles into the approximate width of the hem before it reaches the foot.

Feeding too much fabric in will result in a twisted hem.

Feeding not enough fabric in, will do the same and leave the raw edge not folded under. If you see that you’re losing control, just stop and help a little by pushing the fabric a bit between the needle and the folder.

It will take some practice to master this. Know that different fabric types will react differently, so always practice on a scrap.

SEAMS

If you have to cross a seam while hemming, it can be a little tricky.

Sometimes, a seam passes the fabric folder easily, but often you have to push a little with your awl or a pin. You can also trim to reduce the bulk of seam allowances and maybe use a glue stick to keep the seam allowances flat during hemming. If you’re really stuck, you can put your needle in the down position, lift your presser foot, pull the fabric out the curl, double fold it, put it underneath the presser foot, and sew away. Once you crossed the seam, stop again with the needle down, lift the presser foot up, wriggle the fabric back in the curl and you’re good to continue.

HOW TO END

I use the same technique for the end of a tubular hem. With the end, I mean where you reach your starting point.

If you don’t stop at a corner (the tubular hem), you have to stop at least an inch from the edge or your foot will be stuck in between your stitches. Put your needle down, lift your presser foot, pull out the fabric, put it underneath the foot, stitch and then meet up with the start of your hem.

To end at a corner, press the fabric toward the foot to keep the full allowance in the curl.

TIPS AND INSPIRATION FROM OUR BLOG

Use the wide hem foot for the hem of a skirt as seen here in our gathered summer skirt tutorial.

Discover all the benefits of usng a wide hem foot with our blogger An.